Many secondary processes prior to decorating and bonding require strong adhesion to be successful. However, certain substrates have insufficient surface energy for creating the required bond strength. To bond these types of challenging materials, surface treatment such as plasma or corona treatment significantly improve adhesion. This article will discuss some of the most common bonding challenges and outline how surface treatment overcomes these difficulties.

What Is the Purpose of Surface Treatment?

Surface treatment is used to improve bonding or “functionalize” the surface of a substrate. This useful technology modifies the surface of a material in a way that allows for strong bonds to be formed between the substrate and a label, a coating, print, or adhesive. Surface treatment, such as atmospheric plasma (also called in air plasma) and corona treatment work by improving surface tension. Numerous bonding problems are successfully solved through surface treatment, even those involving elastomeric or polymeric materials.

There are significant costs associated with bonding failure, including poor product field performance, excess scrap and rework, production inefficiencies, and increased quality control. Surface treatment solves virtually any bonding challenge, even when using the most difficult-to-bond materials.

Corona and plasma surface treatment prepare materials for improved adhesion by:

- Raising the material’s surface tension or wettability by altering the molecular properties of the surface

- Improving the bond strength between the applied media and the material

- Plasma treatment provides mechanical etching and micro-cleaning, as well as elevating surface tension

Bonding Items With More Than One Type of Material

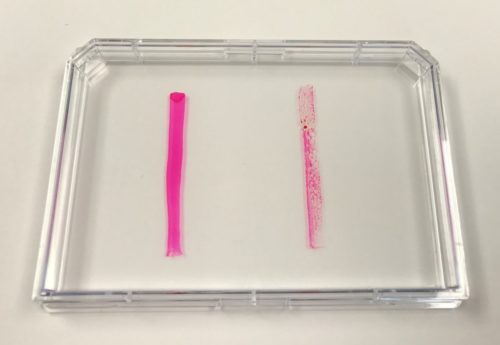

Note how the ink on the left side of the corona treated polystyrene tray fully bonds with the material, but beads up on the non treated right side.

Materials that feature low surface energies, such as those between 20 and 40 dynes, are notoriously difficult to bond. In plastics, this includes materials such as polytetrafluoroethylene (PTFE), polypropylene, and polyethylene, polystyrene, among others. Composite materials are also challenging in bonding applications because the different materials they contain typically feature differing surface energies.

Achieving workable wettability of a substrate requires the surface energy of the substrate to exceed the surface tension of the media being applied. Using surface treatment to increase the substrate’s surface tension causes media to evenly flow and adhere to the material’s surface for highly improved bonding capabilities.

How to Activate the Surfaces of Difficult-to-Bond Materials

When activating the surface of challenging materials, the first consideration should be the surface energy of the substrate. The surface energy will determine whether or not media will successfully bond with the material. Wettability is another prerequisite of successful adhesion. The term wettability describes the ability a liquid has to maintain contact with a type of media. It is influenced by intermolecular interactions that are altered through corona and plasma surface treatments.

Atmospheric plasma is created by combining reactive gas molecules and an electric field. This system uses one or more high voltage electrodes, which charge the surrounding blown gas molecules, resulting in a highly ionized field that is forced onto the targeted surface. This ionized air stream reacts with the substrate and breaks the existing hydrogen bonds by introducing oxygen which recreates the chemical properties of the surface. This intensified reaction causes the material to wet out and accept media, as well as etches and micro-cleans the surface.

3DT’s plasma treatment is not confined to a chamber, but performed in fast, inline production lines. What’s more, plasma is environmentally friendly and potential-free, meaning it can be used on or near metal parts and wiring.

Corona treatment also improves a material’s surface tension to solve bonding problems. It is probably the most common and economical type of surface treatment. In contrast to plasma treatment, corona relies on two electrodes and an isolator to create a cloud of ionized air, corona discharge, that breaks molecular bonds on the surface of a material. Surface oxidation occurs, creating covalent bonds resulting in enhanced wettability and adhesion capabilities.

3DT works closely with its customers in selecting the most appropriate surface treatment method for their application. Factors such as the materials and media involved, the geometry, line speed, and required bonding results are considered. See our blog article What is the Process for Purchasing a Surface Treatment System from 3DT? for more information.

Custom PolyDyne Pro corona treatment system with indexing table for the treatment of labware flasks.

Surface Treatments for Powerful Adhesion from 3DT

Working with materials that are resistant to printing and bonding requires surface treatment processes that improve surface tension and eliminate bonding problems. 3DT manufactures a comprehensive line of surface treatment systems to improve bonding for numerous applications. Our solutions raise surface energy and improve bonding on even the most challenging substrates.

With over 30 years of specialized experience, 3DT provides the most innovative corona and plasma treatment systems. Our equipment addresses the needs of diverse industries and can be used as stand-alone stations or incorporated into a production line. We specialize in process development for demanding applications. Learn more by visiting our corona and plasma treatment process page, or get started on your solution by requesting a quote today.